Kashmiri Willow Industry: Behind the scenes in Srinagar

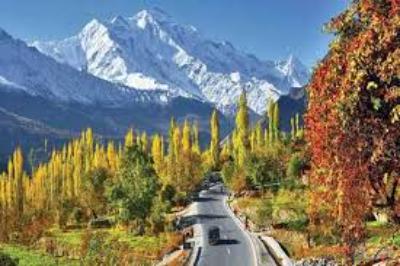

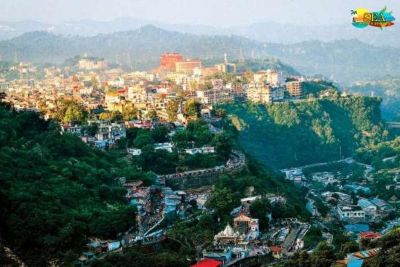

Srinagar, the summer capital of the beautiful region of Kashmir, is not only known for its scenic beauty but also as the hub of the Kashmiri Willow industry. The city, nestled in the picturesque Kashmir Valley, is home to numerous willow groves that produce some of the finest willow wood in the world. In this blog post, we will take a closer look at the fascinating behind-the-scenes process of the Kashmiri Willow industry in Srinagar.

The Willow Groves

The journey of a cricket bat begins in the willow groves surrounding Srinagar. The willow trees grown in these groves are carefully nurtured to produce high-quality wood. Kashmiri willow is known for its strength, flexibility, and lightness, making it the preferred choice for cricket bats across the globe.

The process of growing willow trees in Srinagar starts with planting saplings during the early months of spring. The trees are then carefully tended to throughout the year, ensuring they receive the right amount of sunlight and water. It takes around 10 to 12 years for a willow tree to reach its maturity and be ready for harvest.

The Harvesting Process

Once the willow trees are ready for harvest, skilled workers carefully cut them down using traditional tools. Only the straightest and healthiest trees are selected for the cutting process. The workers make precise cuts to ensure that the trees are not damaged in the process.

After the trees are cut, they are left to dry and season for a period of 2 to 3 years. This aging process allows the wood to gain strength and stability, making it perfect for manufacturing cricket bats. The willow logs are stacked in well-ventilated warehouses, protected from moisture and pests.

The Manufacturing Process

Once the willow logs have adequately seasoned, they are transported to the manufacturing units. Skilled craftsmen then use their expertise to shape the willow wood into cricket bats. The process begins with selecting the best part of the log and cutting it into the desired shape.

The craftsmen meticulously carve the bat's handle, shape the blade, and carefully balance the weight of the bat. It is a laborious and time-consuming process that requires precision and attention to detail. The bats are then sanded, polished, and fitted with a grip to enhance the player's comfort and grip.

The Global Demand

Once the cricket bats are ready, they are sent to various parts of the world. The demand for Kashmiri Willow cricket bats is especially high in cricket-playing countries like India, England, Australia, and South Africa. Top international cricketers often endorse and use Kashmiri Willow bats due to their exceptional performance on the field.

The Kashmiri Willow industry not only contributes significantly to the local economy but also provides employment opportunities to many skilled craftsmen in Srinagar. The industry sustains a rich tradition of woodcraft that has been passed down through generations.

Conclusion

The Kashmiri Willow industry in Srinagar is a testament to the rich cultural heritage and craftsmanship of the region. From the willow groves to the manufacturing units, every step of the process is carried out with precision and dedication. The result is a high-quality cricket bat that is cherished by players around the world.

So, the next time you hold a Kashmiri Willow cricket bat in your hands, remember the behind-the-scenes effort and craftsmanship that went into its creation. Share this blog post to spread awareness about the fascinating Kashmiri Willow industry in Srinagar!

Disclaimer : The information provided in this blog is for general informational purposes only. While we strive to keep the content accurate and updated, TravelSetu assumes no liability for errors or omissions. If you believe any part of this blog infringes your rights or causes concern, please notify us immediately at info[at]travelsetu[dot]com so that appropriate action can be taken.