The Textile Industry of Srinagar: A Deep-Dive into Pashmina Making

The Textile Industry of Srinagar: A Deep-Dive into Pashmina Making

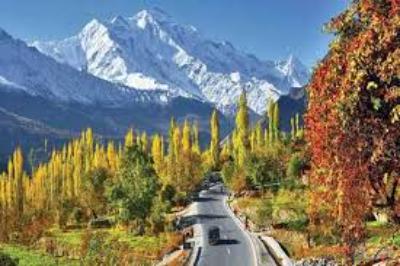

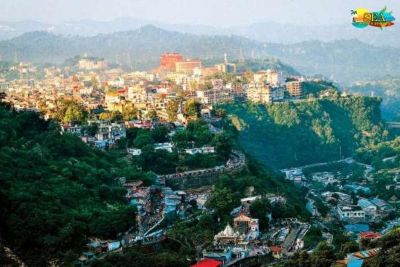

Srinagar, the capital city of the Indian union territory of Jammu and Kashmir, is known for its rich cultural heritage, breathtaking landscapes, and exquisite handicrafts. One of the most prominent industries in Srinagar is its textile industry, which specializes in producing the world-renowned Pashmina shawls.

Introduction to Pashmina:

Pashmina, often referred to as the "diamond fabric," is a luxurious type of wool that is derived from the underbelly of the Changthangi goat, which is indigenous to the high altitudes of the Himalayan region. The wool is known for its exceptional softness, warmth, and durability, making it a highly sought-after material for apparel and accessories.

The Process:

Creating a Pashmina shawl involves a labor-intensive process that has been passed down from generation to generation. Here, I will take you through the intricate steps involved in making these exquisite textiles:

1. Collecting the Fiber:

The first step in the Pashmina making process is collecting the raw material, which is the Pashm wool. The Changthangi goats naturally shed their winter coats, and during spring, the local villagers collect the shed fibers from the rocks and bushes.

2. Sorting and Cleaning:

Once collected, the fibers undergo a rigorous sorting process. Skilled workers separate the finest fibers from the coarser ones, ensuring only the highest quality material is used. The sorted fibers are then thoroughly cleaned, removing any dirt, debris, or impurities.

3. Spinning:

After cleaning, the fibers are spun into yarn by hand or using traditional spinning wheels. This process requires utmost precision and expertise, as the yarn needs to be fine and uniform for the final product to be of exceptional quality.

4. Dyeing:

The yarn is now ready to be colored. Natural dyes derived from plants, roots, and minerals are used to achieve a wide range of vibrant hues. Skilled artisans meticulously dye the yarn, ensuring that the colors are evenly distributed and long-lasting.

5. Weaving:

The most critical step in Pashmina making is the weaving process. Highly skilled craftsmen use traditional handlooms or modern jacquard looms for this meticulous task. The weaving process can take several days or even weeks, depending on the intricacy of the design and the size of the shawl.

6. Embroidery and Finishing:

Once the shawl is woven, it is time for the embellishments. Some Pashmina shawls are beautifully embroidered with intricate patterns, adding an extra touch of elegance. After the embroidery, the shawls go through a process called blocking, where they are stretched and ironed to achieve a smooth and even texture.

The Significance:

Pashmina shawls are not just fashionable accessories; they hold deep cultural and historical significance. These shawls have been a part of Kashmiri traditions for centuries and are often passed down as heirlooms. The fine craftsmanship and intricate designs reflect the rich artistic heritage of the Kashmiri people.

Conclusion:

The textile industry of Srinagar and its Pashmina making process exemplify the exceptional skills and craftsmanship of the local artisans. The creation of these luxurious shawls requires not only technical expertise but also immense patience and dedication. So, the next time you wrap yourself in a cozy Pashmina shawl, remember the remarkable journey it took to reach your hands.

Don't forget to share this fascinating insight into the textile industry of Srinagar with your friends and fellow travel enthusiasts!

Disclaimer : The information provided in this blog is for general informational purposes only. While we strive to keep the content accurate and updated, TravelSetu assumes no liability for errors or omissions. If you believe any part of this blog infringes your rights or causes concern, please notify us immediately at info[at]travelsetu[dot]com so that appropriate action can be taken.